BMSvision WeaveMaster

(Textile MES)

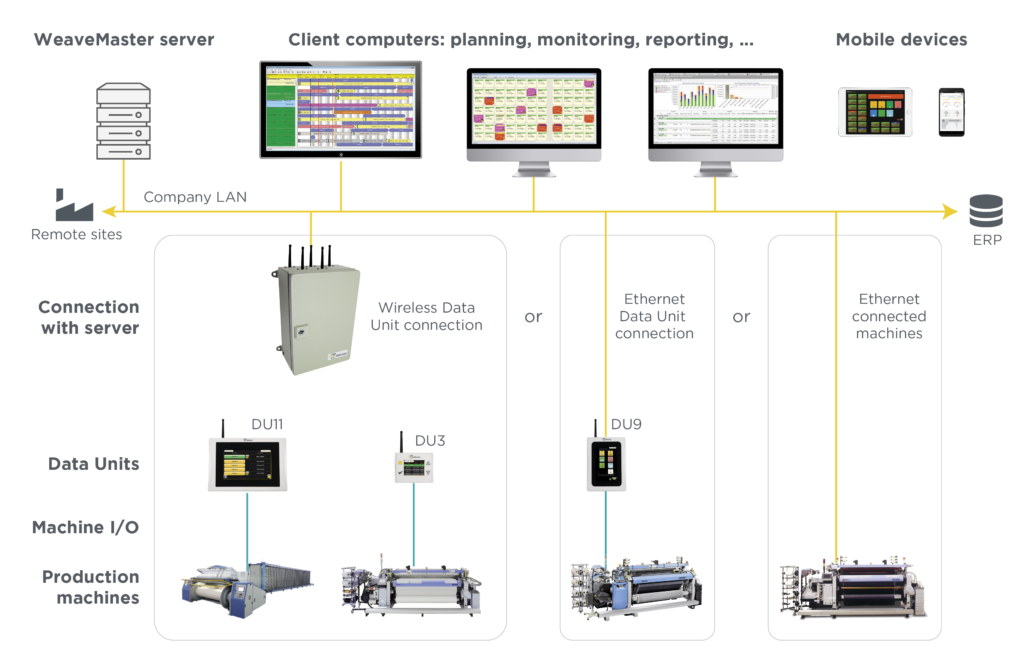

Networking the machines

WeaveMaster supports both cabled and wireless networks to connect the machines to the central server.

Machines are equipped with one of the BMSvision Data Units for automatic as well as manual data collection or linked directly to the server through their built-in Ethernet interface.

Connecting remote sites

WeaveMaster supports the connection of multiple plants to one central server. In the remote sites, M-Servers or WDL-Servers, connected to the company’s intranet, link the machines to the central computer system.

A dedicated “multi-site consolidation module” on the central WeaveMaster server allows integrated reporting for all sites into one single reporting environment.

ERP system integration

WeaveMaster is easily integrated with the customer’s ERP system.

Through a standard interface, order and product data is transferred from the ERP system and imported in the WeaveMaster database.

The integrated export functionality allows a straightforward upload of production data, calculated production schedules, work in progress and performance indicators from WeaveMaster to the ERP system.

System requirements

WeaveMaster is available for 64-bit Windows servers, both on physical systems and in a virtualized environment.

For clients, Windows 7, 8 or 10 is required, or Terminal Services can be used.The database is Oracle driven.

Connecting machines to PlantMaster

Looms with parallel interface, preparation and finishing machines

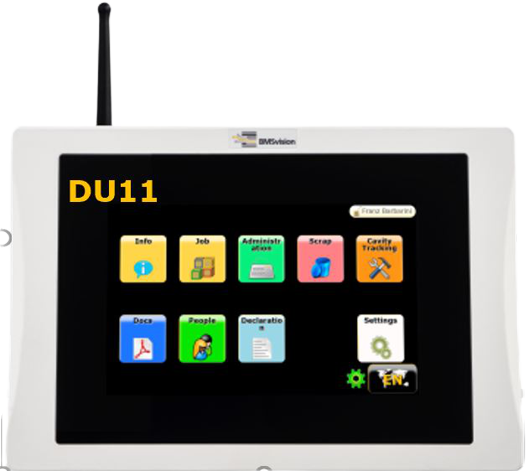

Looms with a parallel interface, warp preparation and finishing machines are connected by means of either DU9 or DU11 Data Units. Production count and automatic stop signals are wired to the parallel inputs of the Data Unit. For looms equipped with the BMSvision Cyclcl-ops on-loom inspection system, the DU11 touch screen Data Unit is used.

The DU9 and DU11 are high end members of the BMSvision data collection terminals. The DU9 features a 5” touch screen. The DU11 features a 7” touch screen and allows displaying various types of production documents. Both Data Units have a web based graphical intuitive user interface.

On screen language selection allows to switch between several western and Asian languages on the spot.

Both Data Units come with wired Ethernet as well as the proven BMSvision Bluetooth based wireless network interface.

Special versions of the DU11 are available for direct and sectional warpers as well as for sizing and finishing machines, allowing real time monitoring of speeds, yarn breaks and eventually process parameters such as temperatures and pressures.

Looms with serial VDI or Ethernet interface

Microprocessor controlled looms equipped with the serial VDI interface are connected by means of the DU7 interface module. Automatic stops are transmitted through the microprocessor’s VDI interface and weavers enter manual declarations through the keyboard and display of the loom. As such, the weaver uses the same user interface for operating the loom as for communicating with the monitoring system. Unlike with other systems, no extra keypad is required.

Through bi-directional communication, the DU7 has access to all information and can activate any function within the machine’s microprocessor.

Latest generation looms equipped with Ethernet interface are either connected through a standard Ethernet network or by means of the DU7 (wired or wireless) in case full back up and recovery is required.

WEB-DU: HMI for multiple machines

The WEB-DU application is used as HMI for a group of machines and can be implemented on any browser enabled touch screen device such as PC’s and tablets.

The individual machines are equipped with a DU2P for automatic data collection (pick count, and automatic stops) while all manual input and information display is handled via the WEB-DU application.