Sedo-Treepoint EnergyMaster

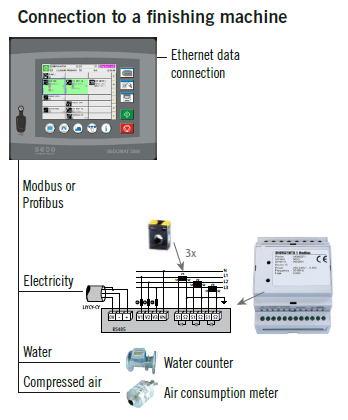

EnergyMaster is the perfect tool for a company to achieve its Energy Efficiency Plan goals. In order to achieve energy management, consumption meters need to be installed in the power switch panel to measure the consumption of machines.

Energy monitoring: reduce carbon footprint – save costs.

The integration of these energy parameters with the production data of SedoMaster provides a perfect insight into the relationship between energy consumption and production, by following the principle of Monitoring and Targeting (M&T), it maps the different energy consumptions (electricity, gas, compressed air, water, steam, effluent, CO2 emission) for further analysis and optimization.

That took place in 3 steps :

Step 1: Measure energy consumption

EnergyMaster targets objectives by monitoring the energy consumption, the company gets answers on important questions such as:

• Which machines or departments are the largest energy users?

• What is causing our peak consumption?

• What about the power factor of our company?

• What about the energy consumption fluctuation of a machine or department over time?

• What is the energy consumption by style and product?

• What is the remnant energy consumption when production is shut down?

• What abnormal consumptions occur and when?

Automatic alerts to managers on exceptional energy consumption via e-mail or text messages, allows for a quick reaction and to realize immediate savings.

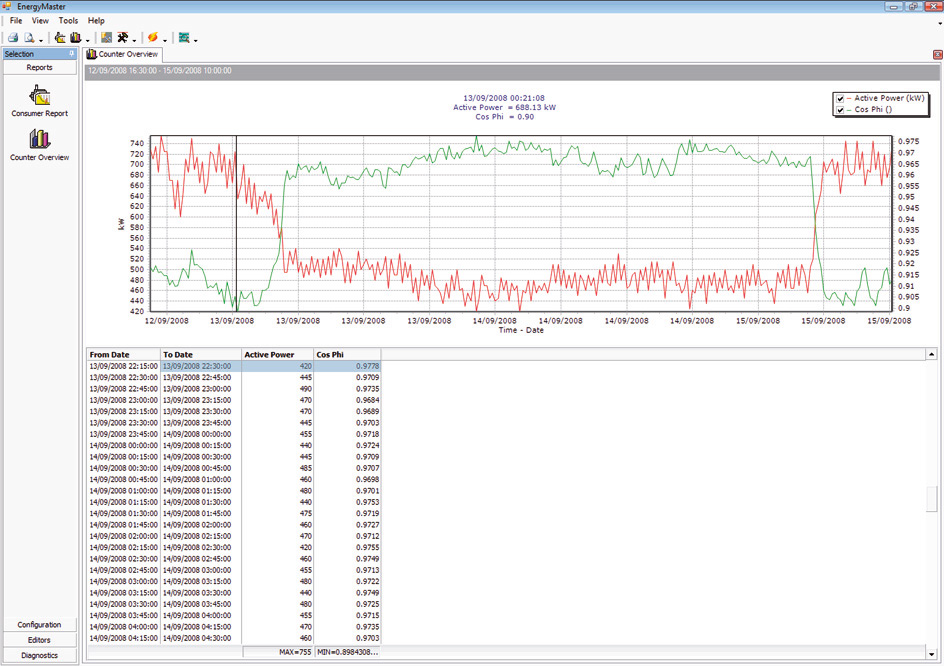

Step 2: Control (Reporting) and target energy consumption consumer reports

Several consumption measurements can be grouped together into one department. As such, dyeing, finishing, weaving, knitting and administration can be defined as a specific consumer.

The consumer reports are graphic reports which show the consumption of a certain department. The user can also select the time period for each group of machines. Line or bar charts can be selected. These reports can be used to trace abnormal peak consumption, to eliminate abnormal consumption and for example to evaluate if reduced night or weekend shifts makes sense, considering the higher energy consumption per unit of production.

History reports

This set of reports shows the energy consumption for a specific machine, for a machine type, for a style or product, for a department or for the whole plant over a longer time period. These reports allow evaluating the energy component in the overall production cost of each product. Does the energy consumption remain constant when a certain style is produced or are there large fluctuations, which require further analysis?

Combination reports

In these reports, energy consumption is related to effective production. For example, in the dye house, energy consumption is reported by batch; in weaving, energy consumption is reported per million picks and in spinning per 10,000 lbs produced. By analyzing this data by type of machine and by type of product, one can determine easily which machine is most energy efficient to produce a specific product or style.

Step 3: Save costs and reduce carbon footprint Consumer reports

With the addition of the module, the SedoTreepoint MES systems are extended with the monitoring of an important cost factor.

By taking advantage of the already present data collection network, data base and server configuration, the investment cost can be kept to the minimum while the monthly energy bill savings can be substantial by using the EnergyMaster module.

By defining an Energy Efficiency Plan with clear objectives, significant energy savings can be realized. EnergyMaster is the right software package to provide analysis and decision support for quick energy saving actions.

It is the right tool to meet government rules for carbon reduction, environmental legislation and last but not least, it will help to protect our environment and leave a better world for future generations.